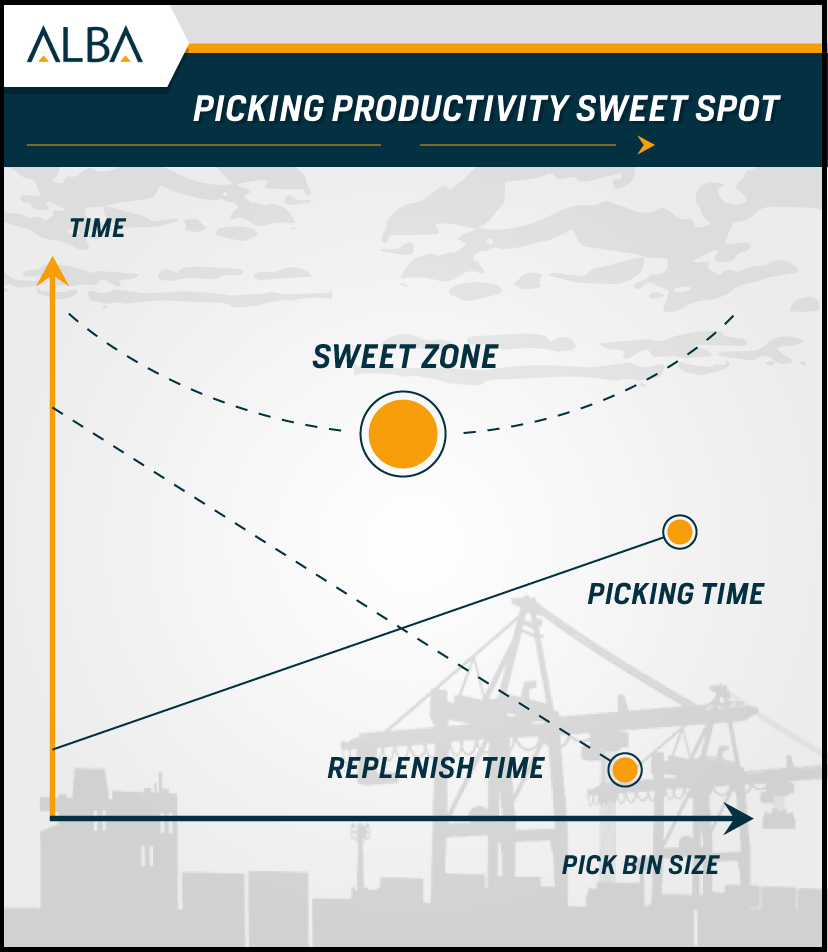

The Picking Productivity Sweet Spot

- In busy order picking operations, the correct selection of pick bin size and capacity for each SKU is fundamental to productivity.

- The larger the pick bins, the further the pickers will have to travel to complete their orders and the time required will increase. This is illustrated on the graphic by the red line rising from left to right.

- On the other hand, the smaller the pick bins, the more frequently the bins will require replenishment and the time required will increase. This is illustrated on the graphic by the green line descending from left to right.

- If we add the total pick time and the total replenishment time together we end up the “hammock” shaped curve represented by the purple line on the graphic.

- The pick bin size for where this combined graph is lowest, that is, around the middle of the graph, is where the total pick time plus the replenishment time is lowest. This is the sweet spot for high productivity.

- Picking and replenishment typically consume 60% to 70% of all labour in distribution warehouse operations. For an operation with just 20 employees, that can be a wage bill of €1 million per annum so is well worth your while to get this right.

- The challenge is to determine the best bin size and location for all SKUs in the stock profile – fast, medium and slow movers to tap into best-in-class productivity levels.

To discuss how we can help you to do this for your operations, contact me directly on +353 86 811 6030 or pdaly@albalogistics.com.